Repair or Replace an Out-of-Warranty Water Heater?

If your water heater is no longer covered by the manufacturer’s warranty, deciding whether to repair or replace it isn’t always straightforward. Homeowners often ask, “Can’t we just fix it?” — and in some cases, the answer is yes. But in many situations, replacement is the safer and more cost-effective long-term option.

Here’s how we help homeowners make an informed decision.

What “Out of Warranty” Really Means

A manufacturer’s warranty covers defects in materials and workmanship for a defined period — commonly 6, 9, or 12 years depending on the model. Once that period expires:

- Parts may no longer be covered

- Tank-related failures are not covered

- Labor is never covered by the manufacturer

- Any repairs are performed at the homeowner’s risk

An expired warranty doesn’t automatically mean a heater can’t be repaired — but it does change the risk profile.

When a Repair Might Make Sense

In limited cases, a diagnostic visit may be worthwhile if:

- The heater is relatively young for its warranty class

- The issue is clearly external to the tank (e.g., thermocouple or ignition component)

- The installation is code-compliant

- There are no signs of corrosion, leakage, or long-term neglect

In these situations, we may offer a diagnostics-only service to identify the cause of failure.

However, it’s important to understand that no warranty is provided on repairs to out-of-warranty water heaters.

Why Repairs on Older Water Heaters Are Often Risky

As water heaters age, several hidden issues become more likely:

- Internal tank corrosion

- Electrolysis damage

- Deteriorated fittings and connections

- Scale buildup due to lack of maintenance

- Components seized in place due to age

Disassembling components on an aging tank can create new leaks or failures, even when the original issue seemed minor.

This is why many professional plumbers — ourselves included — avoid invasive repairs on out-of-warranty tanks.

Code Compliance Matters More Than Most Homeowners Realize

Before any troubleshooting can proceed, the installation itself must meet current plumbing and safety codes.

Common issues we encounter include:

- Missing expansion tanks

- Improper venting

- Inadequate gas shutoffs

- Incorrect seismic strapping

- Non-compliant drain pans or discharge piping

If an installation is not code-compliant, troubleshooting may need to stop until corrections are made. In many cases, bringing an older system up to code significantly changes the cost-benefit analysis.

When Replacement Is the Better Long-Term Option

Replacement is often the smarter choice when:

- The tank is near or past its expected service life

- The warranty has expired

- Multiple components show age-related wear

- Code upgrades are required

- Reliability and safety are a priority

A new water heater provides:

- A fresh manufacturer’s warranty

- Improved efficiency

- Modern safety features

- Code-compliant installation

- Predictable performance

Most importantly, it eliminates the uncertainty that comes with repairing an aging system.

Our Approach: Clear Options, No Pressure

We don’t believe in fear-based sales or unnecessary repairs.

Our process is simple:

- Evaluate the condition of the existing system

- Explain the risks and limitations of repair

- Identify any code compliance issues

- Present clear repair vs. replacement options

- Let the homeowner decide

In many cases, homeowners initially request a repair — and after understanding the full picture, choose replacement because it makes sense for their home and budget.

The Bottom Line

If your water heater is out of warranty, repairs may be possible — but they’re not always advisable.

A professional assessment helps you avoid:

- Spending money on short-term fixes

- Unexpected failures

- Safety issues

- Repeat service calls

If you’re unsure which path is right, a diagnostics-first evaluation can provide clarity without pressure.

👉 Request service or an evaluation HERE

📞 Call: 760-230-5140 / Text: 760-642-6702

📧 Email: info@encinitasplumbingpro.com

Many homeowners are surprised when they experience pinhole leaks in copper piping, especially after replacing an old water heater. What’s often overlooked is the long-term relationship between water heater maintenance, electrolysis, and the health of the entire plumbing system. Understanding this connection can help prevent repeated leaks, costly repairs, and unnecessary pipe replacements. The Role of the Anode Rod (And Why It Matters) Traditional tank-type water heaters are designed with a sacrificial anode rod. This rod—typically made of magnesium or aluminum—is intentionally more reactive than the steel tank and surrounding plumbing. Its job is simple but critical: It attracts corrosive activity It sacrifices itself to protect the tank and plumbing It reduces electrolysis within the system The problem? Most anode rods are never replaced. Recommended replacement schedule: Every 3 years under normal conditions More frequently if the home uses a salt-based or potassium-based water softener When an anode rod is depleted and not replaced, corrosive activity doesn’t stop—it moves into the rest of the plumbing system, including copper pipes. How Neglected Water Heaters Contribute to Pinhole Leaks When a water heater operates for years without a functioning anode rod: Electrolysis increases Electrical potential spreads through the plumbing system Copper piping begins to deteriorate internally Microscopic pits form, eventually becoming pinhole leaks These leaks often appear: Random Isolated Unrelated to visible damage In reality, they’re often the result of years of unseen electrochemical damage. Why Pinhole Leaks Can Continue After Replacing the Water Heater This is one of the most misunderstood aspects of plumbing corrosion. Even after an old, neglected water heater is replaced: The damage already done to copper piping remains Weak points in the pipe walls still exist Leaks can appear months or even years later This often leads homeowners to believe the new water heater caused the leaks, when in fact the deterioration occurred long before the replacement. The new heater didn’t cause the problem—it simply couldn’t undo the existing damage. Water Softeners and Accelerated Corrosion Salt- or potassium-based water softeners can Increase the conductivity of water Accelerate electrolysis when an anode rod is depleted Shorten the lifespan of both the water heater and copper piping Homes with water softeners should be especially vigilant about: Regular anode rod inspections Shorter replacement intervals System-wide corrosion protection Polyphosphate Feeders: Protecting Damaged Systems In homes where electrolysis damage may already exist, installing a polyphosphate feeder can help reduce future pinhole leaks. Polyphosphate systems work by: Coating the interior of pipes Slowing corrosion reactions Helping stabilize weakened copper surfaces While not a cure for severely damaged piping, polyphosphate feeders can be an effective preventive measure to extend the life of a compromised plumbing system. Why Tankless Water Heaters Are Different (and Better for Plumbing) Tankless water heaters do not store large volumes of heated water and do not rely on sacrificial anode rods in the same way tank-type heaters do. As a result: Significantly less electrolysis is generated No long-term stagnant hot water environment Reduced system-wide corrosion risk Improved long-term plumbing health While tankless systems are not appropriate for every home, they offer a major advantage when it comes to protecting copper piping from electrochemical damage. The Big Picture: Plumbing Is a System, Not Individual Parts Water heaters don’t exist in isolation. They are part of a larger plumbing ecosystem. Neglecting maintenance on one component—especially a tank-type water heater—can have long-lasting consequences throughout the entire system, even years after replacement. Proper planning, maintenance, and system-wide protection are the keys to avoiding repeated failures. Professional Guidance Matters Encinitas Plumbing specializes in: Diagnosing pinhole leak causes Evaluating system-wide corrosion risk Anode rod inspections and replacements Polyphosphate feeder installations Tankless water heater evaluations and upgrades If you’re dealing with recurring leaks or want to protect your plumbing long-term, a professional assessment can save you from repeated repairs. 👉 Request service or an evaluation HERE 📞 Call: 760-230-5140 / Text: 760-642-6702 📧 Email: info@encinitasplumbingpro.com

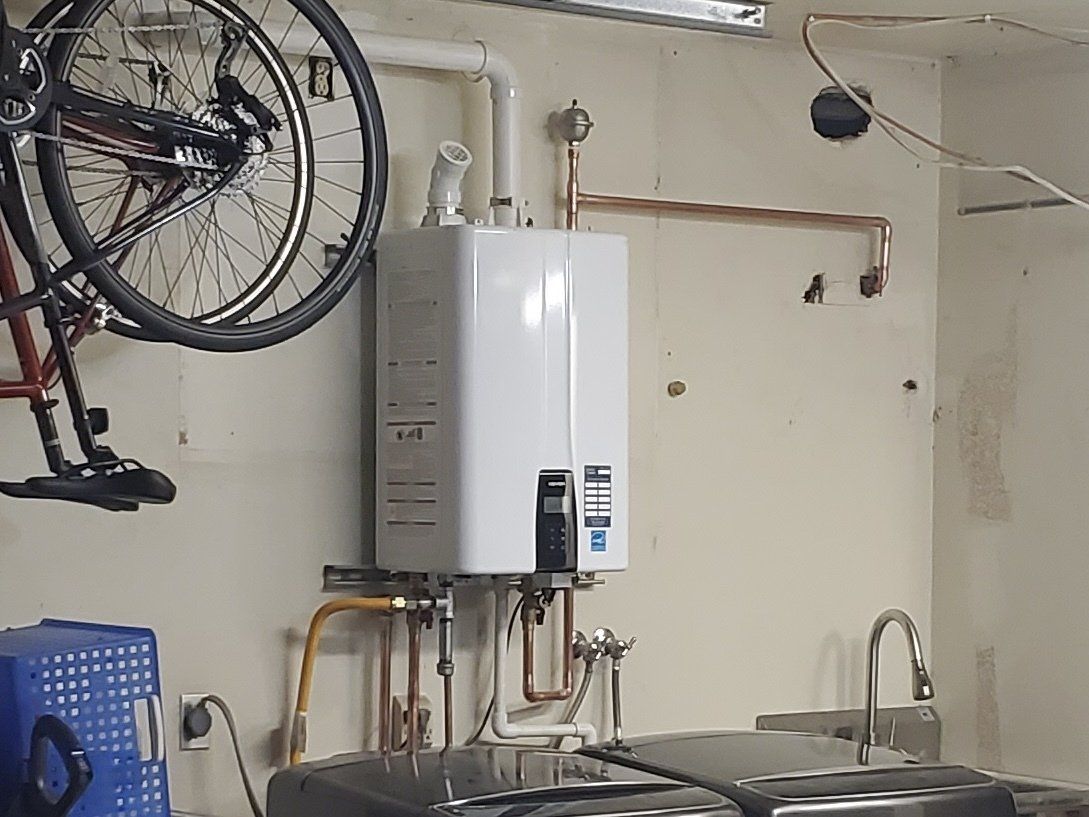

Over the years, we’ve encountered a recurring—and extremely dangerous—installation error involving condensing tankless water heaters: venting them into an existing B-vent (Type B gas vent) system. In some cases, the condensing unit’s PVC exhaust is connected directly into the B-vent. In others, we see a 2” PVC vent run up through an old 3” or 4” B-vent, only to terminate inside the B-vent just inches below the cap, without any sealing between the two pipes. Both scenarios are serious building code violations and present real safety hazards, including the risk of carbon monoxide exposure. Let’s break down exactly why this is unsafe—and why it matters. Condensing Tankless Water Heaters Are Fundamentally Different Condensing tankless water heaters operate very differently from older, atmospheric gas appliances. They: Produce cooler exhaust gases Generate acidic condensate as a byproduct Require sealed, corrosion-resistant venting materials (typically PVC, CPVC, or polypropylene) Use positive pressure exhaust fans, not natural draft Because of these characteristics, condensing tankless units cannot share venting systems designed for older appliances. What a B-Vent Is (and What It Is Not ) A B-vent is a double-wall, metal vent system designed specifically for: Natural-draft appliances Hot exhaust gases Dry venting conditions B-vents are not designed to handle: Acidic condensate Cool exhaust temperatures Positive pressure venting Sealed exhaust systems When condensate from a condensing appliance enters a B-vent, it rapidly accelerates internal corrosion, compromising the vent’s integrity and allowing exhaust gases to escape into surrounding spaces. Why You Cannot Terminate PVC Exhaust Inside a B-Vent 1. Condensate Causes Rapid Corrosion Condensing exhaust contains acidic moisture. When this enters a metal B-vent: The inner liner corrodes quickly Pinholes and separations develop Exhaust gases can leak into wall cavities, attics, garages, or living spaces This is a known failure mode and one of the reasons codes explicitly prohibit this configuration. 2. No Seal = Exhaust Backflow Risk When a PVC pipe exhausts into a B-vent without a sealed transition, there is: No gas-tight connection No pressure control No guarantee exhaust gases exit the structure This creates a condition where: Exhaust gases can spill back down the B-vent Carbon monoxide can migrate into the garage or home Backdrafting occurs under negative pressure conditions Even if the PVC pipe extends “near the top,” inches matter when there is no sealed termination. 3. Positive Pressure vs. Natural Draft Conflict Condensing tankless heaters use fan-assisted exhaust under positive pressure. B-vents rely on: Natural draft Temperature differential Open airflow paths Mixing these systems: Disrupts proper venting Defeats draft mechanisms Creates unpredictable exhaust behavior This is why codes require dedicated, sealed venting systems for condensing appliances. This Is a Clear Building Code Violation Both the California Plumbing Code and manufacturer installation instructions require that: Condensing appliances vent only using approved materials Vent systems be sealed, continuous, and dedicated Exhaust terminate directly to the exterior No exhaust gases be introduced into another venting system Manufacturer instructions are legally enforceable under building code. Installing a condensing tankless unit into a B-vent—directly or indirectly—violates both code and listing requirements. Why We Take This Seriously Improper venting doesn’t always fail immediately. In many cases: Corrosion occurs slowly Leaks develop out of sight Occupants are unaware until symptoms appear Carbon monoxide mixes readily with indoor air and can accumulate anywhere in the home. That’s why venting violations are treated as life-safety issues, not cosmetic defects. When we encounter these conditions, we cannot perform repairs or service on the appliance until the venting is corrected. Proper Solutions Depend on the Site Not every home is a good candidate for a tankless water heater. In some cases: Relocation is required A different venting route must be designed A non-tankless solution may be more appropriate A professional site evaluation is the only way to determine the correct path forward. Work With Certified Professionals Encinitas Plumbing is a Navien NSS-certified dealer and installer, specializing in code-compliant tankless water heater installations and corrections throughout North San Diego County. If you’re concerned about an existing installation—or planning a new one—we’re here to help. 👉 Request Service or a Site Evaluation: HERE 📞 Call: 760-230-5140 / Text: 760-642-6702 📧 Email: info@encinitasplumbingpro.com Your safety—and your home—deserve installations done the right way.

When you’re dealing with a plumbing issue, getting the right kind of service is essential. But many homeowners and property managers aren’t sure whether they need a troubleshooting appointment or a repair appointment . These two types of visits serve very different purposes, and understanding the distinction can help you get your plumbing problem resolved faster and more efficiently. What Is a Plumbing Troubleshooting Appointment? A troubleshooting appointment is all about diagnosis . If you're not sure what's causing a leak, a clog, or strange noises in your pipes, a plumber will come out to assess the situation. This visit involves: Inspecting plumbing fixtures, pipes, and systems Running diagnostic tests (like pressure tests or camera inspections) Identifying the root cause of the problem Recommending the next steps for repair or replacement Common reasons to schedule a troubleshooting appointment: Unexplained water stains or damp spots Low water pressure without a known cause Foul odors or gurgling sounds in drains An appliance or fixture isn’t working properly, and the cause isn’t clear You’ve had repeated plumbing issues that need deeper investigation 🔧 Can issues be fixed during a troubleshooting visit? Sometimes, yes. If the issue is minor and can be safely and efficiently resolved during the same visit (such as a quick adjustment or small clog), the plumber may go ahead and fix it on the spot. However, more complex issues, or those requiring parts or extensive labor, will require a follow-up repair appointment . What Is a Plumbing Repair Appointment? A repair appointment is scheduled when the problem has already been identified, and the goal is to fix it. At this point, the plumber knows what tools and parts are needed and comes prepared to complete the repair. This appointment typically includes: Replacing broken or leaking pipes Repairing or replacing faulty fixtures (faucets, toilets, water heaters, etc.) Clearing known clogs Fixing or sealing known leaks Addressing issues already diagnosed during a troubleshooting visit Common reasons to schedule a repair appointment: You've already had a troubleshooting visit and know what needs to be done A prior plumber or inspection revealed the exact issue You need a specific part or system fixed (e.g., “replace the leaking faucet,” “repair the broken shutoff valve”) Why It’s Important to Schedule the Right Type of Appointment Scheduling a repair appointment when the problem hasn’t been diagnosed can cause delays. The plumber may not have the right parts or tools with them—or worse, the issue might be something completely different than expected. Likewise, booking a troubleshooting appointment when you already have a diagnosis can be redundant and may add unnecessary cost or time. Not Sure Which to Choose? Start with Troubleshooting. If there’s any uncertainty about the source of the problem, a troubleshooting visit is the safest first step. Many plumbing companies (including ours) will credit the troubleshooting fee toward the repair if you choose to move forward with the work. Conditions apply — credit may depend on the nature of the repair, time elapsed between visits, and total cost. Ask us for full details when booking your appointment. Let’s Get Your Plumbing Back on Track Whether you're dealing with leaks, clogs, or mystery plumbing issues, our expert team is ready to help. 📞 Call us at (760) 230-5140 📅 Schedule your appointment online at: https://www.encinitasplumbingpro.com/schedule-appointment Not sure what kind of appointment you need? No problem — our friendly staff will walk you through it.

What are the differences between a hard water scale prevention device and a backflush carbon filter?

What are the differences between a hard water scale prevention device and a backflush carbon filter?

Share On: